Our expertise

Harvest

Numerous grains can be used to make whisky, but barley produces the finest aromatic expression. The harvested barley undergoes a mashing process, in which the grains are moistened for several days and then spread out to promote sprouting. Once sprouting has begun, it is transferred to an oven for around 30 hours to slowly dry out. The barley is milled to a coarse powder called “grist”, then mixed with water and heated to create a paste called the “maische”. This is filtered and cooled to obtain the must, to which yeast is added which will transform its sugars into alcohol.

DISTILLATION

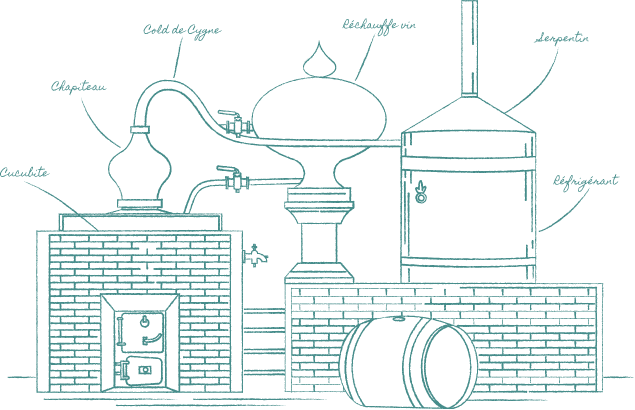

The resulting product is then twice distilled in a traditional copper still.

A perfect still

As with Cognac, the “heads” (the initial liters of liquid which appear) and the “tails” (the last liters to be produced) are discarded during the “coupe” made by the distiller. Only the heart is retained and put in cask.

Cooperage

Although the preceding steps are key in defining the character of the future whisky, aging in oak casks—three years, minimum—in the environment of the cellars determines the intensity and complexity of the aromatic palette, as well as the color and the subtle hue, from pale gold to dark amber. Finally, the distilled liquid is concentrated if needed, to reach the final alcoholic degree for bottling.